Reconstruction of locomotive shed

Reconstruction of the locomotive shed

Aim of the project

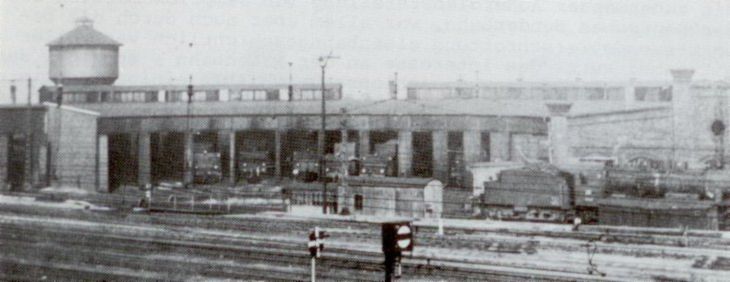

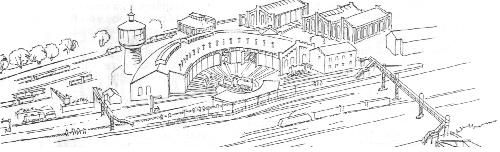

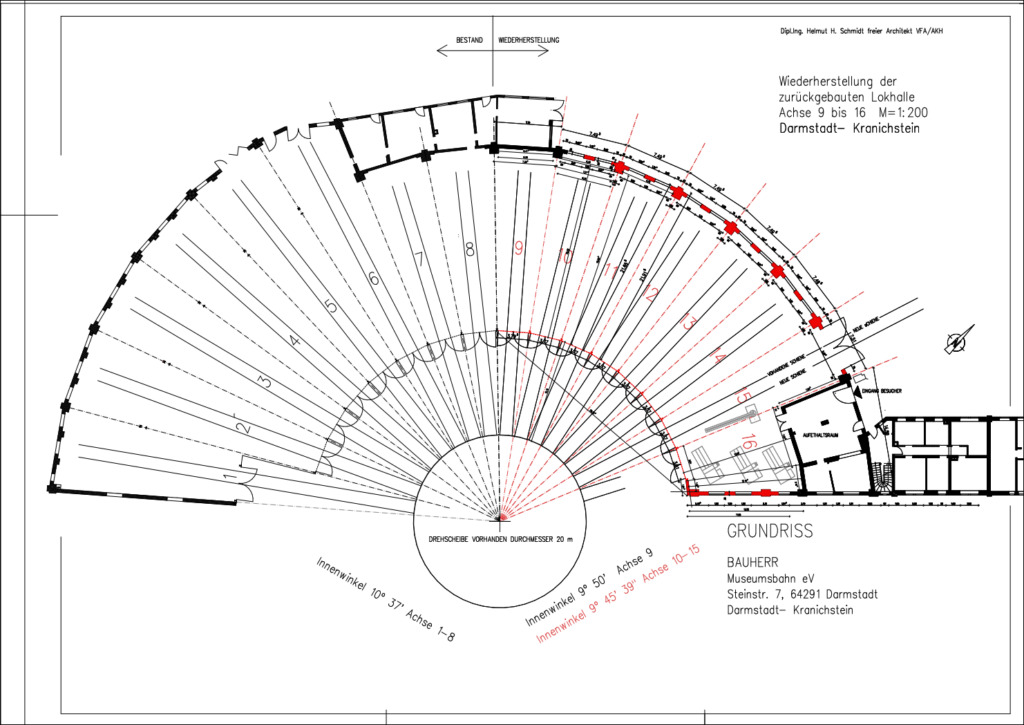

A long-cherished goal of the Bahnwelt Darmstadt-Kranichstein is the re-erection of these eight shed stands in order to be able to shelter further parts of the historic vehicle collection protected from the weather on a total of 15 stands. This will allow us to present the depot again in its original form.

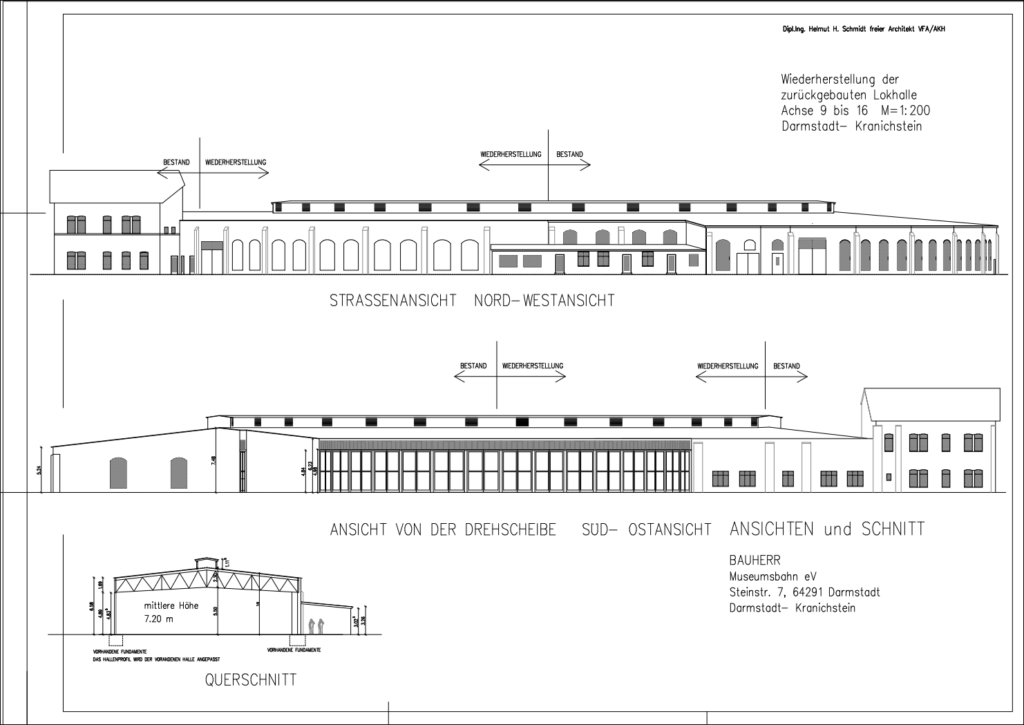

On the basis of approved construction plans, a project order was defined in 2016 that provides for the reconstruction in two construction phases, initially as an open hall structure in steel construction. In a third construction phase, the hall will be provided with exterior walls, gates and technical infrastructure. As parts of the derelict marshalling yard and the depot were designated as an area monument (“Darmstadt’s longest monument”) in 2017, the reconstruction will be carried out as a “new building in the existing structure” in close coordination with the monument authority.

Project financing

Since the completion of the planning, donations have been raised for this project, which were supported by Darmstadt’s Lord Mayor Jochen Partsch with a press- and publicity-accompanied ground-breaking ceremony in 2016 and the laying of the foundation stone in 2019.

Our thanks go to the following institutions and companies who supported the project with generous donations so that work on the first construction phase could begin as early as 2018:

-

Sparda-Bank Hessen 30.000 €

-

Sparkasse Darmstadt 200.000 €

-

Association of Friends and Supporters 10.000 €

-

Bahnwelt Betriebs GmbH 10.000 €

-

Gruber+Hartmann Tragwerksplanung GmbH 10.000 €

-

Ringfeder Power Transmission GmbH 10.000 €

The sum of the earmarked funds so far is expected to enable the completion of the first phase of construction. Rapidly rising steel prices and the general increase in costs due to the Corona pandemic are additional challenges for the declared project goal. However, the high proportion of continuous own work by the association members contributes significantly to achieving this goal with the available funds.

Documentation of the reconstruction

Reconstruction of locomotive shed: Ceremonial ground-breaking at the 2016 Bahnwelttage

On the occasion of the anniversary Bahnwelttage 2016 “40 years railway museum”, the ground-breaking ceremony for the reconstruction of the roundhouse took place with representatives from the politics of the city of Darmstadt, the sponsors of the museum, the commissioned architect and friend of the Bahnwelt, Helmut Schmidt, representatives of the railway directorate Mainz, the Royal Prussian and Grand Ducal Hessian State Railways as well as the surrounding state railways.

Reconstruction of locomotive shed: Exposing the foundations (September 2018 until May 2019)

The reconstruction of the locomotive shed stands began with “archaeological excavations”, during which the still existing foundations of the former shed stands 9, 10 and 11 were uncovered.

Above from left to right: With an excavator and a lot of manual work, the existing remains of the natural stone foundation of the former rear shed wall are first exposed piece by piece. According to structural specifications, the foundations had to be removed to 1.40m below the upper edge of the track so that the new steel-reinforced foundations could be built on top. The track yokes laid in the 1980s on the backfilled investigation pits were initially left on site.

Above from left to right: The foundations facing the turntable were also carefully exposed, and a parallel drainage channel made of clinker masonry was excavated down to the bottom. This so-called “ring channel” had been filled with building rubble when the old locomotive shed was demolished.

Reconstruction of locomotive shed: Concreting the new foundations (February until May 2019)

After the old foundations had already been successively uncovered in 2018, preparations for the construction of the ring beams on the old foundations could begin on the basis of the verified statics. On 18.05.2019, the superstructure concreting of the front ring beam was then carried out. For this purpose, the terrain had to be surveyed in advance and an elaborate formwork and steel reinforcement had to be erected – all done by the club members themselves. For the first construction phase over three hall tracks, 5t of steel and 17cbm of concrete were used just to strengthen the foundations on the gate side and on the back wall of the shed.

Assembly of the new locomotive shed doors (May 2019)

The work on the locomotive shed as the central building of the railway museum includes not only the reconstruction of the second half of the shed, but also extensive measures on the existing building. Since December 2008, in cooperation with the trainees of the training association for metal (AVM) Rüsselsheim, work has been continuously carried out on the reconstruction of shed gates made of a wood/steel construction with window elements, in order to gradually replace the green steel gates that were getting on in years. A few years ago, the gate at the back facing Steinstraße was renewed. Now the first gate on the turntable side could finally be installed. The newly acquired two-way excavator was a great help. The years between production and installation were used to paint the gates, to install the wooden infill and to glaze in about 600 panes of glass with about 600 kg of window putty so far.

At this point, we would like to thank the following partners and companies:

- AVM Rüsselsheim

- Carpentry Pfeiffer, Groß-Umstadt

- Carpentry Traser, Darmstadt

- EGO Dichtstoffe, Garmisch-Partenkirchen

Reconstruction of locomotive shed: Laying of the foundation stone (May 2019)

Darmstadt’s Lord Mayor Jochen Partsch celebrated the start of construction with the laying of the foundation stone on Ascension Day, 30 May 2019 at 11.00 am. In keeping with tradition, coins, a daily newspaper, the list of names of the members of the city council, the board of the museum railway and the construction plans, were cast into the foundation in a steel quiver. The special feature: the steel quiver is made of a smoke pipe from a steam locomotive. Members of the association in historic railway uniforms formed the framework for the laying of the foundation stone.

First picture from left to right: project manager Stephan Heldmann, Lord Mayor Jochen Partsch and museum director and first chairman of the Museumsbahn e. V. Uwe Breitmeier.

Reconstruction of locomotive shed: Exposure of the rear foundation (July to August 2019)

After gaining experience during the concreting of the first ring beam to strengthen the front foundation, the work to strengthen the rear foundation had to be repeated. First, the existing foundation had to be exposed. This is easier than in the front area, as it is not covered by the tracks that were temporarily laid after 1970. However, the rear wall of the locomotive shed is considerably longer, so that more extensive earthmoving measures are necessary. After a survey and structural evaluation of the existing structure, the necessary steps for retrofitting were determined. The top layer of clinker masonry, loosened by moisture and frost, was demolished, as were the first three rows of quarry sandstone masonry underneath.

After completion of the excavation and demolition work, the contour of the foundation is clearly visible (see second picture above). The layer now achieved is load-bearing and can serve as a basis for concreting a ring beam, analogous to the procedure in the front area.

Through careful and layer-by-layer demolition by hand, many of the original clinker bricks and also a large amount of quarry sandstone could be recovered. Some of these were stored for repair work on the existing locomotive shed (see third picture above).

Reconstruction of locomotive shed: Concreting the rear foundation (September 2019 to January 2020)

The reinforcement was calculated by our structural engineer and bent by our steel construction partner. The installation is carried out on site according to the installation plan. The thorough monitoring of the work process by at least one observer per worker is a natural part of our quality assurance.

After the reinforcement has been placed correctly, the formwork for the concrete work has to be made. For cost reasons and because the shape of the existing foundation has to be taken over, only the production of the formwork on site in timber construction is possible.

When aligning the formwork, special attention must be paid to the height in order to be able to lay the tracks correctly later. The reinforcement is then aligned with the formwork so that the required concrete cover is achieved everywhere and the new foundation is permanently durable. Empty pipes are provided to penetrate the foundation for the later introduction of supply and disposal lines into the locomotive shed.

The highlight of the work was the pouring of the concrete on 21 December 2019. Approximately 10 cubic metres of concrete were used during the three-hour operation. Two truck mixers were used for delivery, which drove to the construction site one after the other. After the concrete had been poured, it was compacted and the surface was stripped and reworked.

We would like to thank the following companies for their support:

Hofmann-Rieg Stahlhandel, Darmstadt (fabrication and delivery of the reinforcement)

Waibel KG, Gernsheim (delivery of the concrete)

The new year begins with the stripping of the formwork. The formwork is then dismantled, the formwork timber is cleaned and stored for reuse.

Reconstruction of locomotive shed: Laying the supply and disposal lines (February 2020 to April 2020)

The still existing excavation pit will be extended in order to lay the supply and disposal pipes. Dirty water and rainwater will be routed separately so that the rainwater can later be collected in the cistern that is yet to be built and will be available to us as feed water for the locomotive boilers (low lime content).

Empty pipes will be laid for the subsequent supply of drinking and service water as well as for the electrical and telecommunications lines. These will be provided with inspection shafts at regular intervals so that the corresponding cables and lines can be easily pulled in later and maintained if necessary.

The planned empty pipes for penetrating the foundation are used to lay cables inside the locomotive shed.

After completion of the civil engineering work, all trenches will be backfilled and compacted in layers up to the top edge of the ground. Due to the clayey soil, soil improvement by adding lime will be necessary in some areas in order to be able to compact the soil sufficiently. Dust is stirred up to a not inconsiderable extent in the process.

Reconstruction of locomotive shed: Clearing the construction site and removing the tracks (May 2020)

Due to a lack of personnel capacities and disposition, the construction work has to be temporarily interrupted, as the further steps first require the clearing of the construction site. Among other things, a collection of historical shape and light signals is stored on the partition wall between track 8 (existing “new building”) and track 9 (demolished “old building”).

This makes work in the area of the wall and the roof impossible. There is also a risk that the signals could be damaged or knocked over by “enemy contact” with construction machinery. Therefore, the signals are loaded onto a freight wagon and stored away for the time being. With the help of the two-way excavator, the work could be carried out with only three men within one working day despite intermittent heavy rain.

Now that some of the vehicles in the museum area have been moved, the last remaining small cars can be moved out of the construction site. Now nothing stands in the way of removing the temporarily laid tracks from the 1980s.

Of course, this measure is also being carried out by the project team. First, all rail fastenings are dismantled and then the rails are removed.

Since most of the rails are still usable and will be reused in future track rehabilitation work, they are stored temporarily outside the construction site.

This is followed by the removal of the sleepers. These are also stored for reuse elsewhere. Various open freight wagons serve us for this purpose.

The remaining ballast superstructure is removed and disposed of. Subsequently, the entire base area will be stripped down to the bare floor level. As this is below the height of the already completed new foundations, a temporary construction road must be created so that construction vehicles can continue to drive into the construction site. The dismantled wooden sleepers are partly used for this purpose.

Reconstruction of locomotive shed: Dealing with the existing investigation pits (June to July 2020)

Now the upper edges/heads of the historical inspection pits filled in during the demolition in 1970 are also exposed. Just like the newer part of the locomotive shed, the old building already had pits bricked in clinker with a length of approx. 15 m and access stairs to be able to carry out maintenance work on the locomotives from below. In the part to be rebuilt, it is not planned to maintain the pits in an accessible and usable condition for reasons of time and cost. However, from the point of view of monument preservation, it is necessary to document the design and location of the pits. For this purpose, they will be uncovered one after the other.

It turns out that the backfilling at the time was mainly done with building rubble. This is sieved out and disposed of.

Cleaning is followed by surveying and photo documentation. Then the pits are backfilled and compacted so that the new tracks to be laid in these areas rest on a stable subsoil.

In order to meet our high quality standards and achieve the best compaction performance, the work is carried out by our railway authority certified top compaction officer.

The exposed pits will be used to lay additional empty pipes between the rear and front areas of the locomotive shed.

Reconstruction of locomotive shed: Dealing with the existing drainage/ring channel (August to September 2020)

The historic drainage/ring channel in the area of the front foundations on the inside of the locomotive shed is similar to the investigation pits. Preserving it in working order as a walk-in drainage structure would involve a great deal of effort and expense, but its usefulness for museum purposes would be extremely limited. Here, too, a solution was worked out in close consultation with the lower monument protection authority of the city of Darmstadt. This envisages documenting the canal. It will be used to lay supply and disposal lines and then backfilled. In this way, it will be indirectly preserved for posterity and nothing would stand in the way of a possible reactivation in the case of a renewed demolition and new construction after another 130 years.

In order to access the pipelines to be laid for maintenance purposes during later operation, inspection shafts are being prepared in the area of the track axles.

Reconstruction of locomotive shed: The unforeseen looms (October 2020)

After surveying and static testing, it was determined that the existing wall between track 8 and track 9, which currently closes off the locomotive shed, cannot be retained. It was erected in 1970 as a temporary solution when the old locomotive shed was demolished, but it is neither load-bearing nor profile-free. Therefore, further construction of the locomotive shed must be interrupted in order to first erect a new partition wall. Here, the construction meeting with our structural engineer is taking place.

Reconstruction of locomotive shed: Preparations for new partition wall (November to December 2020)

The existing partition wall was measured in order to be able to draw up a plan for the new wall. In addition to static calculations and plan drawings, this also required an additional building permit including test statics. The new partition wall will be erected as a steel framework with brick-lined bays. The necessary steel girders were made by a specialised company and delivered to the construction site in mid-November. Here, an additional coating was applied. Now all materials for the construction of the new partition wall are ready to start immediately with the erection of the new wall after the demolition of the existing wall. Due to bad weather and the pandemic, work had to be suspended for a few weeks.

We would like to thank the following companies for their support:

Hofmann-Rieg Stahlhandel, Darmstadt (coordination and delivery).

Gesellschaft für Stahlbau und Schweißtechnik mbH, Hattersheim (fabrication of the steel beams)

Reconstruction of locomotive shed: New architect (January 2021)

Since the first considerations in 2008, the Darmstadt architect, Helmut Schmidt, has been overseeing the project on a voluntary basis and with great commitment. He used his 84th birthday last year as an opportunity to think about a gradual retirement from active professional life 😉. Now that the above-mentioned changes to the plans and approvals for the construction of the new partition wall have been obtained, the overall planning for the reconstruction of the locomotive shed is largely complete. Now it is up to the association to implement them in a timely manner. In addition, Helmut Schmidt’s revised financial planning and cost estimates last year also set up the project in such a way that the city of Darmstadt and our sponsors have promised us further financial support. During a ceremony on 08.01.2021, Helmut Schmidt was honoured for his achievements. As a token of appreciation, he received a 1:87 scale model of a class 95 steam locomotive for his large model railway, which, by the way, is located in his offices: late in the evening after work was done, it was not uncommon for the regulator on the transformer to be turned up once again and the late train to be driven: To “come down”, as he says. We hope to be able to welcome him to the museum many more times as an honorary member. And we are sure that he will still have one or two building tips from his rich professional experience.

The supervision of our project will be continued from 2021 onwards by the Darmstadt architect Jens Daube (Planinghaus Architekten), who has taken over all the documentation and has been trained by Helmut Schmidt.

First picture from left to right: structural engineer Prof. Dipl.-Ing. Klaus Fäth, museum director and first chairman of the Museumsbahn e. V. Uwe Breitmeier, architect Jens Daube, architect Helmut Schmidt, chairman of the Friends and Supporters Association Werner Pielhauer, project manager Stephan Heldmann.

Reconstruction of locomotive shed: Concreting of the front support on the ring channel (December 2020 to February 2021)

In the course of preparing the subgrade in the locomotive shed area so that the tracks could later be laid and the floor slab concreted, it became apparent that the rear wall of the ring channel in the upper area no longer had sufficient load-bearing capacity. Therefore, it had to be strengthened, just like the foundations. Unlike the foundations, however, the wall consists entirely of clinker brickwork. The loose rows were removed. Then the reinforcement was laid and the formwork prepared. Now we are waiting for frost-free weather to start the concreting work.

Reconstruction of locomotive shed: Concreting of the front support on the ring channel (March to April 2021)

Due to the long period of cold weather with night frost into March, we were not able to concrete the front support at the ring channel until the end of March. The time until then was used to prepare smaller concreting works in other places in the area as “official assistance”. Among other things, this concerned an entrance ramp to the pipe workshop and a broken manhole cover. The concrete left over from the locomotive shed was to be used here so that it would not have to be disposed of.

We traditionally pour concrete on Fridays and before public holidays… 😉. After preparing our equipment, the truck mixer with the concrete arrived punctually on 26.03.2021 at 10.00 am. Within one hour, almost 5 cubic metres of concrete were placed.

A total of six club members were in action, always working at corona-compliant distances. The special challenge this time was to move the entire quantity in concrete buckets with the excavator across the construction site to the ring channel. Otherwise, we would have had to order a concrete pump, which would have been uneconomical due to the small quantity and would have caused high additional costs.

After the Easter holidays, the formwork could be removed, cleaned and stored for drying and further use. The freshly concreted support was trimmed, with special attention paid to the entrances of the later inspection shafts.

Reconstruction of locomotive shed: Demolition of the partition wall between track 8/9 (March 2021 to June 2021)

As already reported in October 2020, the existing partition wall between tracks 8 and 9 needs to be renewed. It had been erected in 1970 after the demolition of the old part of the locomotive shed and formed the temporary outer wall of the locomotive shed to the east. First, material stored on the inside of the wall was moved so that sufficient safe working space was now available inside and outside. Then a protective net was installed to protect the vehicles parked in the locomotive shed from falling construction debris.

The first step towards the actual demolition of the partition wall was the controlled chiseling free of the right- and left-sided connection of the wall with the roof posts of the locomotive shed. The connection of the wall to the roof was also separated. The wall, which was free-standing on all sides, could then be rapidly demolished in three sections with the help of heavy equipment, whereby the construction debris was placed on the prepared area outside the locomotive shed.

The now missing wall provides new and at the same time unusual insights into the locomotive shed … but there is a considerable draught! All those involved in the project are therefore endeavouring to rebuild the partition wall as quickly as possible. Temporarily, construction fences have been installed as burglary protection.

In the coming weeks, the rubble had to be removed.

In the axis of the new partition wall to be erected, the remains of the foundation of the old wall were demolished until a load-bearing and level substructure for a new foundation was produced.

Reconstruction of locomotive shed: Partial rehabilitation of the existing roof truss (June 2021)

The prepared area was first used to set up scaffolding to access the existing roof truss. This was cleaned and inspected. In some places, there were strong signs of corrosion due to water penetration, because the connection of the temporary wall to the existing roof had also only been carried out very provisionally. In order to better assess the condition of the roof trusses, it was decided to completely derust at least the lower chord. Because of the paints used at the time (asphalt varnish, lead red lead), appropriate work safety precautions had to be taken. Fortunately, after cleaning the steel structure, no excessive weakening of the cross-section became apparent. Since the roof truss will be relieved in the future anyway by the trusses of the new partition wall to be attached, no further measures were necessary. A new anti-corrosion coating was applied.

For their support, we would like to thank:

PROSOL Lacke + Farben GmbH, Darmstadt (corrosion protection coating and tools).

Heinrich Geil Baggerarbeiten, Trebur-Geinsheim (construction waste removal and disposal)

Reconstruction of locomotive shed: Erection of the steel supports (July 2021)

Before the foundation could be concreted, the steel supports for the new partition wall had to be erected. Together with the crossbars to be installed later, these form the steel framework, which will then be bricked up. First, the position of the posts had to be measured. Then core drillings were made in the old foundation, the post anchors aligned and grouted with swelling mortar.

After it had hardened, the steel posts were erected with the help of the two-way excavator and fixed to the anchors at the bottom. At the top, they were fixed to the existing roof truss.

Reconstruction locomotive shed: Construction of a point foundation (excursion) (July 2021)

A section of the back wall of the old locomotive shed from 1889 was preserved when it was demolished in 1970 because it also forms the back wall for an adjoining workshop building, which was not demolished. This is where our sheet metal workshop is located today. As a result, the masonry post between tracks 9 and 10, on which the associated roof truss originally rested, was also preserved. It was planned to use this post again as a support for the new roof truss. However, a close inspection of the post revealed that it was badly damaged by frost and weathering and no longer had any load-bearing capacity. In order to be able to use it again, demolition and new construction would be unavoidable, and the foundation might also have to be strengthened. Since the extent of this work is hardly assessable and, in addition, would have required further intervention in the currently used building stock with corresponding restrictions on use, an alternative solution was developed. The post will later be strengthened and integrated into the continuation of the outer wall, but will no longer have a static function. Instead, a new point foundation is concreted directly in front of the post and a steel support is erected, which then carries the new roof truss. This construction method deviates from the design planned for the other track axes, but very clearly marks the transition to the reconstructed part and is thus also to be approved of from a monument preservation point of view.

The first step was to dig a pit for the foundation. In the process, we came across old water pipes that were no longer in use and had to be removed. Then the soil of the excavation pit was compacted, whereby soil improvement became necessary to increase the stability. In the course of the formwork and reinforcement work on the foundation of the partition wall, this foundation is also prepared so that everything can be concreted together.

Reconstruction locomotive shed: Raw soil levelling (July to August 2021)

In preparation for the track laying planned for autumn, work has already begun on clearing the construction site and levelling it to raw soil level. The subgrade is now being compacted. Subsequently, load plate pressure tests will be carried out to ensure the load-bearing capacity of the substructure. This is to exclude, as far as possible, changes in the position of the tracks, settlement phenomena and cracks in the concrete floor inside the locomotive shed.

Reconstruction of locomotive shed: Production of the foundation for the partition wall (August to September 2021)

After the steel supports were installed and aligned, the reinforcement was laid on the partition wall. Since the existing foundation could also be partially retained here and only the upper part and the visible base had to be newly concreted, a level foundation was provided and the work proceeded quickly. Making the formwork took more time, as it had to be individually adapted to the local conditions. The formwork was made of wood. In the area of the later base, work had to be particularly clean in order to obtain a flawless exposed concrete surface.

The concreting work took place on 24 and 25 September. On Fridays, the point foundation was poured and the non-visible part of the partition wall foundation was pre-concreted. This method was necessary because the foundation is L-shaped. In order to concrete it in one piece, a cover formwork would have had to be installed and weighted down with weights or anchored in the ground. By working in two steps, this effort could be saved, but another concrete delivery was necessary on Saturday. During the concreting, numerous helpers from the association were on duty on both days. The two-way excavator and the wheel loader were used to move the concrete within the construction site.

The remaining concrete was used to repair some defects in the courtyard and to provide a new bottom for the drainage ditch in the turntable pit, so that water and dirt can no longer accumulate here.

We would like to thank the following companies for their support:

- Hofmann-Rieg Stahlhandel, Darmstadt (Fabrication and delivery of the reinforcement)

- Waibel KG, Gernsheim (Delivery of the concrete)

Formwork and backfilling

The following Saturday, the formwork could be removed, dismantled, cleaned and stored for further use. The areas of the construction site that had been walked on and driven over during concreting were levelled again and recompacted.

The point foundation contains a lead-through for four empty pipes. These had to be connected to the empty pipes already in the ground. The working pit was then backfilled and compacted in layers.

Reconstruction of locomotive shed: Extension of track 10 (September 2021)

The plans envisage extending track 10 about 13 metres beyond the rear wall of the locomotive shed. A corresponding gate is to be provided later in the rear wall of the locomotive shed. In the area accessed by the track, a lathe and an embossing polishing machine for wheelsets are currently installed. This makes it possible to roll and process axles removed via the axle sink in tracks 1 and 2 directly in front of these machines via the turntable. In preparation for laying the track, this area was excavated so that a substructure of mineral concrete could later be laid on which the track would be built. Beforehand, a cable duct was installed as a crossing under track 10 in order to be able to lay further lines (water, sewage, electricity, telecommunications) behind the locomotive shed in the future without having to remove the track again.

Reconstruction of locomotive shed: Survey and soil expertise (September 2021)

The track construction work is now firmly scheduled for the beginning of October 2021. They will be carried out by an external company. In a preliminary meeting, it was determined which preliminary work had to be done by us and how the construction site was to be handed over. On the one hand, the position of the axles of the new tracks 9 to 11 to be built, had to be precisely marked in the terrain. For this purpose, a surveying office was commissioned to make the markings on the newly constructed foundations, starting from the centre of the turntable. On the other hand, the load-bearing capacity of the raw soil in the construction area had to be checked, as it had been partially filled in, partially removed and repeatedly levelled and compacted during the construction process so far. An engineering office for geotechnics was on site for two days with two employees and carried out static load plate pressure tests as well as a review and inspection of the construction site.

We would like to thank the following companies for their support:

- Vermessungsbüro Gläßer, Darmstadt (carrying out the surveying work)

- Geotechnik Gündling, Darmstadt (execution of the load plate compression tests)

Reconstruction of locomotive shed: Track construction (October 2021)

In preparation for the track construction, two articulated lorries with a total of 160 concrete sleepers were delivered on 8 September. These had to be unloaded and temporarily stored on the site within one hour.

On Monday, 04 October 2021, the company AGT arrived punctually at 7 a.m. with machines and tools and began the track construction, which was planned to last two weeks. On the same day, the rails and steel sleepers were delivered. In addition, mineral concrete for the ballast base layer was delivered at regular intervals, which always had to be placed immediately due to the cramped conditions in the construction area.

In the area towards the turntable, the dirty ballast was removed, the subgrade was compacted and work began on laying the sleepers.

Three steel sleepers are then followed by concrete sleepers until the end of the respective track. The construction work and the construction logistics were organised so efficiently that by the end of the working day all sleepers for the first track (track 9) had already been laid and the rails could be laid. In the same way, tracks 10 and 11 were built in the following days.

By the end of the first week of work, all three beam tracks had been laid. The rails were bolted down, then the tracks were tamped and aligned.

The second week began with the welding of the rails, which had previously been separated at right angles. An arc welding process was used for this. The weld seams were ground at the rail head and on the inside of the rail so that the joints are no longer visible. Subsequently, the affected sleeper compartments had to be filled and tamped by hand in order to bring the track into the final position at the welding point as well.

In addition, the spaces between the sleepers and the areas between the tracks were backfilled and compacted. This forms the subsoil for concreting the floor slab. Since a constant height had to be maintained within narrow limits and due to the cramped conditions on the construction site, manual labour was sometimes unavoidable.

The work was completed with the dowelling and grouting of so-called individual support points, which fix the track at the points where it crosses the foundations and where therefore no sleepers can be laid.

With the departure of the construction company, the immediate surroundings and the driveways were also levelled and made passable again.

In addition to the AGT employees, two club members were always on the construction site. In order to keep the costs for us as low as possible, it was agreed that we would be allowed to carry out auxiliary and ancillary work (transport of materials, etc.). In addition, it proved to be advantageous that a contact person was always directly available in order to be able to directly clarify any questions that arose regarding the determination of the track position or the execution of details.

We would like to thank the following companies for their support:

- Allgemeine Gleis- und Tiefbau-Bauunternehmung GmbH, Mainz, Darmstadt branch (execution of the track construction work)

- Betonwerke Moll, Biebesheim (delivery of the concrete sleepers)

Reconstruction of locomotive shed: Completion of the steel truss construction for the partition wall (November to December 2021)

Reconstruction of locomotive shed: Delivery of building material (January to April 2022)

Reconstruction of locomotive shed: Assembly of the ruts in the locomotive shed area (February 2022)

Reconstruction of locomotive shed: Wall construction (May to July 2022)

- Immo Herbst Garten- und Landschaftsbau (provision of the stone saw)

Generous donors for the reconstruction of the demolished roundhouse

On Tuesday, 5 December 2023, two visibly cheerful gentlemen did the railway museum the honour of handing over their generous donations for the reconstruction of the demolished roundhouse. Thomas Moka from Ringfeder Power Transmission (Groß Umstadt) and Markus Hartmann from Gruber+Hartmann Tragwerksplanung (Darmstadt) ceremoniously handed over their cheques for €10,000.00 each to Werner Pielhauer, Chairman of the Museum Railway Association. The fact that two such large donations could be received was by no means a foregone conclusion.

Thomas Moka, Managing Director of Ringfeder Power Transmission, was looking for a suitable “location” for the 100th anniversary of his company. With a special steam train and subsequent company celebration in October 2022, the company’s choice of location also reflected its corporate roots, as buffers for railway carriages were also manufactured at the beginning of its existence.

Markus Hartmann, owner of Gruber+Hartmann Tragwerksplanung, has had a close relationship with the railway museum for several years. Initially “only” commissioned by the board of directors to carry out the structural analysis of the roundhouse to be rebuilt, he and his staff ultimately also wanted to celebrate in this iconic atmosphere in June 2023.

Both were so enthusiastic about their celebrations and the successful realisation by the association’s volunteers that they signalled their continued support for this ambitious locomotive shed project in discussions. It was almost a matter of course that the association’s board of directors invited the local press to attend and at the same time publicly thanked the donors. The two companies will also be “immortalised” with their logos on the donor plaque on the construction site sign. A third donor was unable to attend for scheduling reasons: Helmut Schmidt, a structural architect from Darmstadt Arheilgen, had subsequently donated his extensive planning services for the building permit to the association free of charge.

He, too, will receive a proof of donation on the building site plaque as thanks for his generosity.

Markus Hartmann (second from left), Werner Pielhauer (centre), representing the architect Helmut Schmidt, and Thomas Moka (right) present the stickers for the construction site sign on the listed administration building. Hans Gunkel (left) represents all the voluntary members of the association involved in this project and their work.

Werner Pielhauer (in uniform) explains the construction work to date and the associated investments to our donors at the newly raised partition wall between the old and new parts of the engine shed: Around 3500 hours of voluntary labour went into replacing the ground, building the wall, concreting the ring foundations and laying the track. An additional € 180,000.00 was spent on materials and outsourced construction work.