Last trip for ELNA 184 DME

On Saturday, 03.07.2022, the ELNA was fired up to perform cab rides on the following Sunday as part of the July operating day on the site. This was the last time the locomotive will be used for the time being, as the main running gear inspection is now due, which we will now bring forward by just under a month in order to have the locomotive ready for use again in time for trips in the autumn and winter.

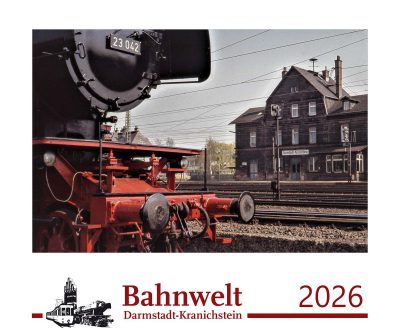

Picture left: In the evening light 184 DME is ready for tomorrow’s service, opposite the partially painted 23 042 looking out of the shed.

First firing up of the 23 042 is imminent

Work is also progressing on 23 042. In the next few weeks, we would like to finally fire up the locomotive again for the first time. Before that, a few small things still need to be completed. For example, the impact pot of the blowdown valve was repaired after severe corrosion, painted with a heat-resistant paint and can now be reinstalled soon. In addition, the wooden floor on the locomotive driver’s side was completed. The four-way valve for the pneumatic cylinder of the fire door was also assembled and repainted.

Furthermore, the locomotive’s paint scheme is increasingly being completed. In addition to painting the running gear, the light covers were repainted in signal yellow.

Further work on locomotives and wagons

Work also continued on the V62. While the rewiring is nearing completion and the visual appearance of the locomotive is also almost finished, the commissioning of the locomotive will follow soon.

Not only in the locomotive workshop things went well. We also had a small “aha effect” with the passenger coaches. During the main inspection of Bi 84 803 we tried to reactivate an external generator drive unit after a long period of inactivity. And lo and behold, it runs perfectly! This means that the light generators under the wagons can now also be driven when the wagons are stationary and thus the wagon electrics can be tested.

Unfortunately, there is also less positive news from this project. The brake linkage of the wagon needs a bit more care and attention than initially thought. By measuring the bolts and bushings, about 60% now have to be replaced and renewed due to wear. The brake triangles are machined on the lathe and the bores of the remaining components are bored out centrically again on the Strassmann boring machine for pressing in the new bushings. The new procurement of the bolts and bushes according to DIN for rail vehicles now costs another 2,500 €. We would therefore be delighted – as with every one of our projects – to receive your support:

Donation account:

Keyword “Support Donnerbüchse”

Sparkasse Darmstadt

IBAN: DE68 5085 0150 0000 6088 58